Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Country of Origin

- Tilley Product Number

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

Applications & Uses

- Markets

- Applications

- Applicable Processes

Properties

- Physical Form

- Typical Properties

Value Units Test Method / Conditions Isocyanate Equivalent Weight ⁽²⁾ ⁽¹⁾ 125.5 - - NCO Content ⁽²⁾⁽¹⁾ 33.5 wt.% - Hydrolyzable Chloride Content ⁽²⁾⁽¹⁾ 18 ppm - Acidity (as HCl)⁽¹⁾⁽²⁾ 0.003 % - Viscosity (at 43°C)⁽¹⁾⁽²⁾ 5 cPs - Density (at 43°C)⁽¹⁾ 1.18 g/ml - Vapor Pressure (at 43°C)⁽¹⁾ max. 10⁻⁴ mm Hg - Extrapolated Boiling Point ⁽¹⁾ 314 °C - Approximate Decomposition Point ⁽¹⁾ 230 °C - Flash Point ⁽¹⁾ min. 177 °C ASTM D 93, Closed Cup Specific Heat ⁽¹⁾ 0.43 gm•cal/gm•°C - Thermal Conductivity ⁽¹⁾ 0.0003 gm•cal/cm•sec•°C - Coefficient of Thermal Expansion ⁽¹⁾ 0.0009 kg/l/°C - Heat of Vaporization ⁽¹⁾ 86 cal/gm - Heat of Fusion ⁽¹⁾ 32.6 cal/gm -

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

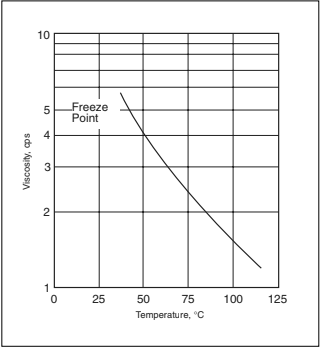

- Viscosity vs Temperature

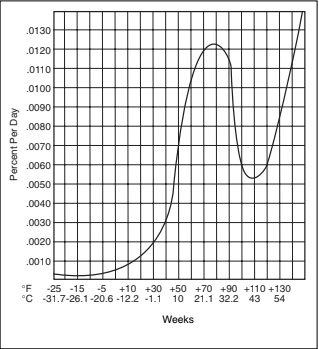

- Rate of Dimer Formation

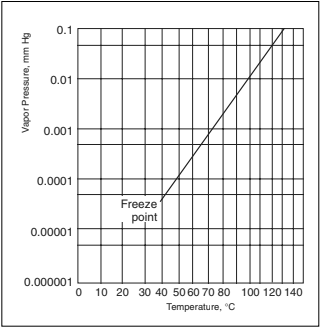

- Vapour Pressure vs. Temperature

- Approximate Storage Life of ISONATE 125M pure MDI at Various Storage Temperature

Temperature Storage Life °C (°F) Days (1) (2) (3) -17.8 (0) 300 -12.2 (10) 210 -4.4 (40) 68 10 (50) 33 25 (77) See note (4) Below

40.6 (105) 31 43.3 (110) 35 46.1 (115) 35 48.9 (120) 28 The Table Shows the approximate Storage Life of ISONATE 125M pure MDI at Various Storage Temperatures.

- Storage life is taken as the period of time during which the product can be melted to a clear liquid by melting procedures recommended.

- Storage life includes the average storage time at plant or warehouse.

- Storage life of solid product is not valid when shipped in non-temperature-controlled vans.

- Temperature ranges between 21.1°C (70°F) and 37.8°C (100°F) give a minimum dimer growth of 0.0114 percent per day and wildly erratic results in many recorded instances.

- Note

⁽¹⁾ : Not to be construed as specifications.

⁽²⁾ : For test procedures, see Technical Bulletin 109-774, “ISONATE Pure and Modified MDI Test Procedures.”

⁽³⁾ : Shelf Life Under recommended handling conditions (clear melt without filtration).

Safety & Health

- Safety Measures

- Diphenylmethane diisocyanate is irritating to the respiratory tract and can cause respiratory and skin sensitization in susceptible individuals. Although vapor pressure is low, there is the possibility that the diphenylmethane diisocyanate (MDI) may exist in aerosol droplets which may provide air concentrations that would be hazardous upon single exposure.

- These effects may be delayed. Decreased ventilatory capacity has been associated with exposure to similar isocyanates; it is possible that exposure to MDI may cause similar impairment of lung function.

- In case of inhalation exposure, remove to fresh air, consult medical personnel.

- MDI may cause eye and skinirritation. In case of eye contact, irrigate immediately and continuously with water for at least 15 minutes. Consult medical personnel.

- In case of skin contact, wash off material in flowing water or shower, remove contaminated clothing immediately and launder before reuse. Destroy contaminated shoes and leather items.

- The single dose toxicities of pure and modified MDI are low. If ingested, do not induce vomiting. Consult medical personnel.

Storage & Handling

- Shelf Life

- 365 days (at -20°C), 45 days (at 43°C)

- Product Handling

- Workers should wear appropriate eye protection (safety glasses are considered a minimum requirement and if there is the possibility of exposure to the eyes, it is recommended that chemical goggles be worn) and protective clothing impervious to MDI whenever MDI is used.

- General or local exhaust ventilation should be provided to control airborne levels below the exposure guidelines.

- The vapor pressures of pure and modified MDI are low at room temperature (<1 X 10-5 mm Hg). However, at temperatures over 104°F (40°C), the vapor pressure increases enough that low functionality MDI products begin to constitute a toxic hazard.

- Storage Information

- Recommended storage temperatures for ISONATE 125M pure MDI are, as solid, below 0°F (-18°C). This product can withstand temperatures of 0° to 25°F (-18° to -4°C) during short-term shipping (less than two days).

- Recommended shipping and storage temperatures for ISONATE 125M pure MDI, as a liquid, are 110° to 118°F (43° to 48°C) for four weeks or less.

- Melting Instructions

- If drum shipments of polymeric or modified MDI products arrive in a crystallized, frozen or fused state, they should be promptly unloaded and heated as soon as possible.

- Polymeric, pure and modified MDI products that have been frozen will exhibit the same dimerization characteristics as pure MDI. Unless proper action is taken to heat or melt the product, dimerization will proceed rapidly and deteriorate both the clarity and assay of the product.

- While several methods for melting frozen or crystallized MDI have been developed, the method of choice should be one in which dimer formation is minimized. This can best be accomplished by rapid, even heating of the drums, as follows.

- The preferred method for heating drums is “drum rolling” (usually at 5 rpm on a mechanical drum roller) in atmospheric steam. The principal advantage of this method is that it permits efficient heat transfer – that is, the solid MDI crystals cool the liquefied material so that the contents are not heated much beyond 70°C (158°F), the point at which dimer formation can increase significantly.

- Experience has shown that a frozen drum of polymeric, pure or modified MDI, with a temperature between -4° to 32°F (-20° to 0°C), will usually melt completely (i.e., reach 70°C [158°F] in approximately four to five hours).

- Also, while 70°C (158°F) is significantly higher than the recommended storage and handling temperature, it is necessary to reach this temperature, at least briefly, in order to melt the product both quickly and thoroughly.

- Before heating, any opened drums should be reblanketed with dry nitrogen (-40°F [-40°C] dew point) and all drums, previously opened or not, should have bungs tightened securely. Upon removal from the steam chest, residual heat will usually evaporate free water from the drum head. In any event, the top of the drum should be wiped with a dry cloth.

- As can be seen, agitation and even heating is the key to maintaining quality during melting. Dow does not recommend static melting in hot-air oven or with electric heating apparatus, or by hot-water bath.