Enhanced TDS

Identification & Functionality

- INCI Name

- Tilley Product Number

- Cosmetic Ingredients Functions

- Technologies

- Product Families

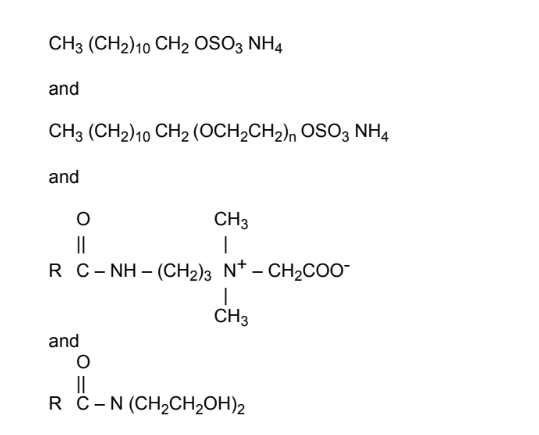

- Chemical Structure

Features & Benefits

Applications & Uses

- Markets

- Applications

- Application Format

- Hair Care Applications

- Personal Hygiene Applications

- Product Applications

- STEPANOL AEG is a concentrated surfactant blend for use in shampoos, liquid handsoaps, and bath products.

- STEPANOL AEG exhibits excellent foam and viscosity characteristics. It offers ease of handling and simple mixing and dilution attributes.

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Safety & Health

- Toxicity Information

- The toxicology of major components that make up STEPANOL AEG blend (Ammonium Lauryl Sulfate and Ammonium Laureth Sulfate) is well known.

- Ammonium Lauryl Sulfate is slightly toxic orally (LD50 is 3-5.5 g/kg) and causes moderate to severe eye and severe skin irritation at 10% active.

- Ammonium Laureth Sulfate is slightly toxic orally (LD50 > 5g/kg) and causes mild eye irritation at 7.5% test solution and no skin irritation at 0.07 and 0.14% test solution.

Packaging & Availability

- Packaging Information

STEPANOL AEG is available in 55 gallon drums (net weight 450 lb/204 kg).

Storage & Handling

- Storage Condition

- Normal safety precautions (i.e., use of gloves and safety goggles) should be employed when handling STEPANOL AEG.

- Contact with the eyes and prolonged contact with the skin should be avoided. Wash thoroughly after handling material.

- It is recommended that STEPANOL AEG be stored in sealed containers and kept at temperatures between 40°F (4°C) and 120°F (49°C).

- Avoid overheating or freezing. If material is frozen, mild heat and agitation are recommended to ensure the material is homogeneous before use.